Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Previously, direct printing of corrugated board was the domain of flexographic printing. Today, offset printing presents a good market opportunity due to the excellent quality of its four-color printing.

The transformation of packaging and printing The development of direct offset printing of corrugated board is based on the premise that the design of corrugated boxes is changed to four-color printing.

If a few years ago, storage and transportation packaging was still based on monochromatic or two-color field or line printing, people today have demanded that the original appearance of the goods be genuinely printed on their packaging, through this high-quality packaging appearance. Printed to show the excellent quality of the packaged product.

The successful development of a new type of corrugated board has made important contributions to the direct offset printing of corrugated board. As the market demands less and lighter packaging, the new type of fine corrugated cardboard has attracted attention, but a certain degree of stability can be achieved with the corrugated boxes produced by it.

In recent years, there have been many innovations and developments in this field. This development is mainly to meet the needs of offset printing. Fine corrugated cardboard is particularly suitable for printing with an offset press. The stability of G- and F-type corrugated paperboards is very good, and there is no problem in field printing.

This development, as well as external influences (relevant regulations for the packaging of goods), have brought about tremendous changes in the entire corrugated box printing market. In this way, years of disputes between offset printing and flexo printing have subsided. Because what kind of printing method is not important, improving the quality and economic efficiency of printed products is the most important.

People have already abandoned the way of dividing the printing market with newspaper printing, part printing, offset printing, flexo printing, gravure printing and screen printing. Instead, the market is divided into three parts. This division is based on the product, not on the printing method. Offset presses are also equipped with flexo coating units, which are no longer used for printing but rather fulfill their mission in terms of quality and economy. This also contributes to the development of direct offset printing of corrugated board.

It has been a long history for Manroland to continue to develop direct offset printing technology for corrugated board. 1970 and 1971. Manroland has introduced the corrugated board direct offset printing technology to the public. However, the process was not yet mature at the time. Therefore, no one at the time seriously considered printing corrugated cardboard directly with an offset press. Later Flexo began its pioneering work in this area. (To be continued)

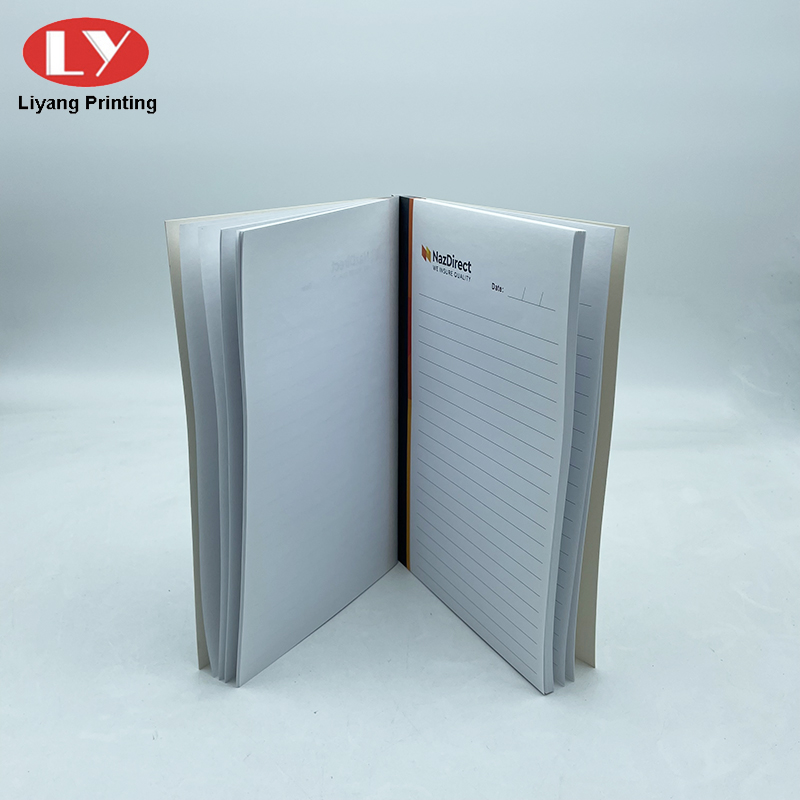

accet custom catalog printing, brochure printing, notebook printing, paper folder, paper envelope.

November 12, 2024

November 10, 2024

October 31, 2024

October 30, 2024

E-posta denna leverantör

November 12, 2024

November 10, 2024

October 31, 2024

October 30, 2024

Skicka förfrågan

Ms. Lily Yu

Tel:86-769-81228313

Fax:86-769-85193253

Mobiltelefon:+8613925768389

E-post:admin@lyprinting.com

Adress:Shuishang Village, Renzhou Administrative District, Shatian Town, Dongguan City, Guangdong Province, 523999, China., Dongguan, Guangdong

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.